Smart

Manufacturing

Platforms

From goods receipt to finished product - PromasCS digitizes and controls every production step for maximum transparency, efficiency and quality.

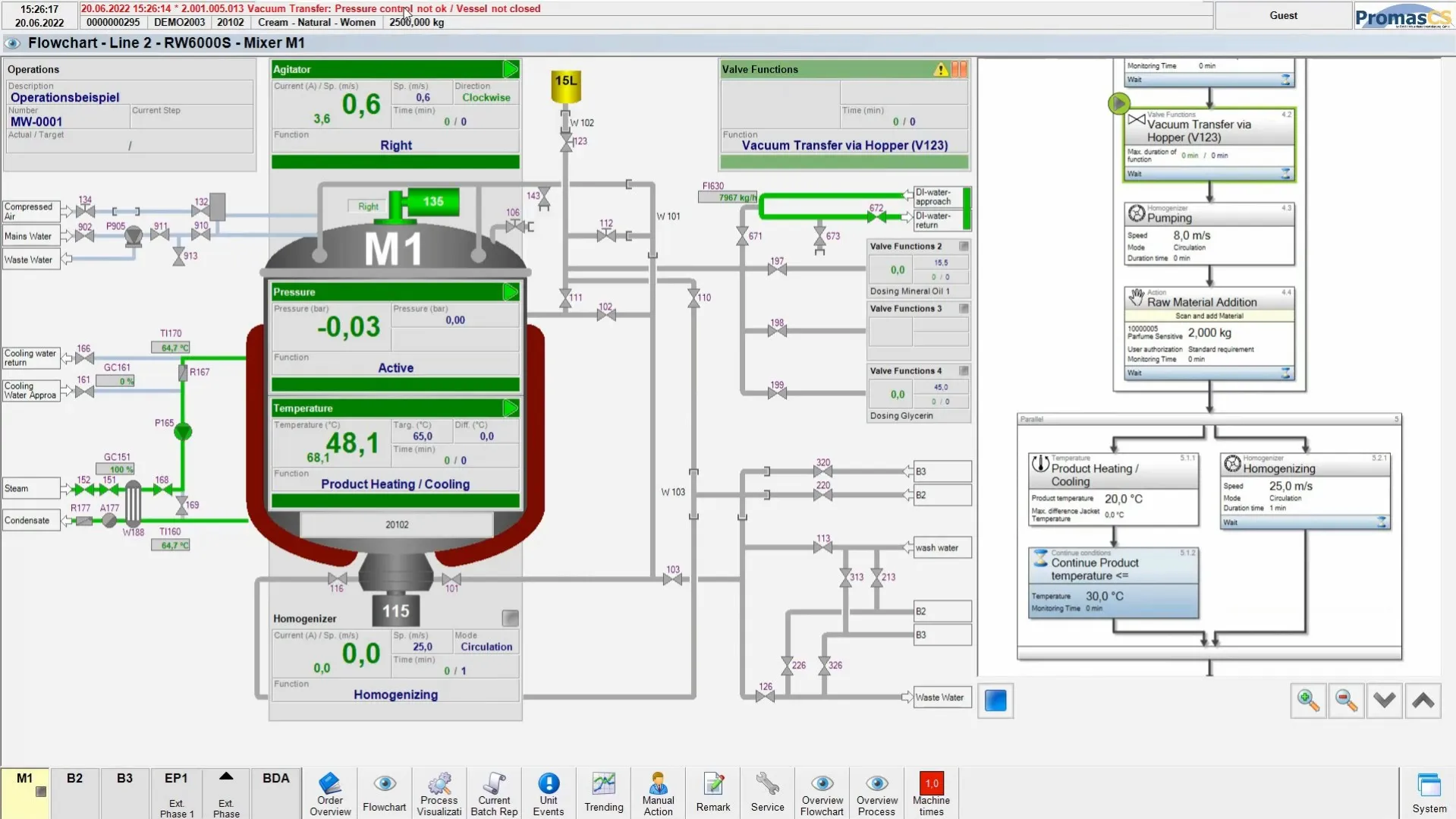

All in one system – control, control system & MES seamlessly integrated

PromasCS combines the control level, the process control level (operating and monitoring) and the Manufacturing Execution System (MES) in a single, fully integrated platform.

Consistent data – from the field device to the management level

All data throughout the production process is centrally recorded, evaluated, and analyzed – from measurement data acquisition at the field level to organization and visualization at the MES level. The result: maximum transparency and seamless integration across all levels.

Integrated Business Intelligence – for transparency in production

The integrated, web-based BI module enables simple and user-friendly visualization of your production data. Dashboards, key performance indicators, and analyses provide valuable insights – for informed decisions, continuous improvement, and greater efficiency in production.

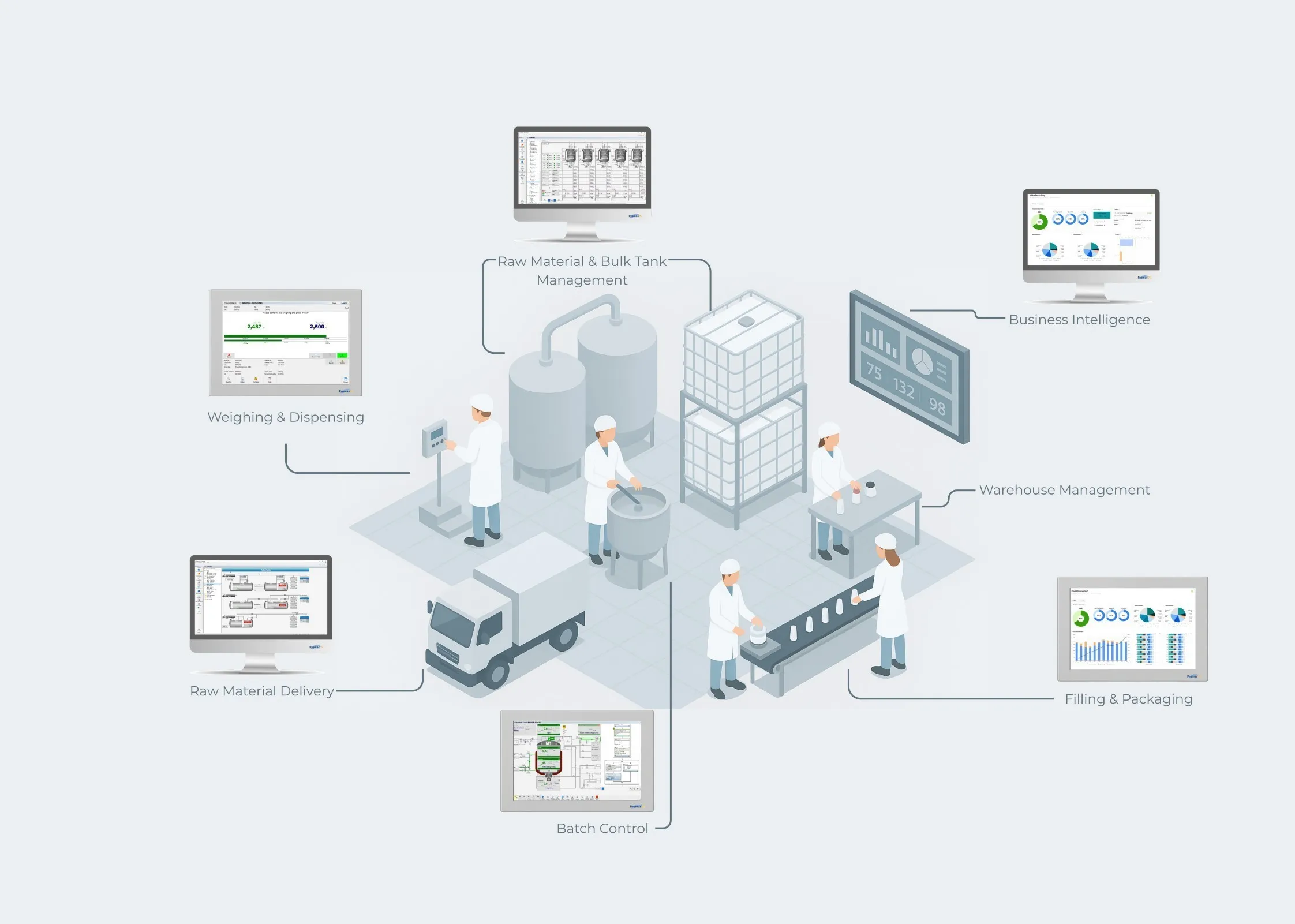

One Solution for the entire production chain

From raw material delivery through storage, weighing and dosing, production, and filling and packaging to subsequent process analysis: PromasCS digitalizes and controls every step along the production chain. The consistent digitalization and integration of all processes ensures maximum transparency, efficiency, and quality - from goods receipt to the finished product.

PromasCS – the modular MES for automating production processes for manufacturers in the pharmaceutical, chemical, cosmetics and food industries.

- One system for everything

A system that combines MES and process control system (PCS/SCADA) – from raw material delivery to final packaging. This sustainably reduces training requirements for operating personnel.

- Increase productivity & reduce effort

PromasCS maximizes efficiency through a high degree of automation, ensures consistently high quality thanks to reproducible batch processes, and creates transparent, optimized production processes.

- Intuitive & efficient

Thanks to the user-friendly interface, getting started is quick – even without any programming knowledge. Production processes can be designed efficiently and intuitively directly on the system's control panel. The highly standardized architecture and no-code approach enable easy configuration of entire process and cleaning sequences.

- Scalable & flexible

From a small laboratory system to a complete production line – PromasCS grows with your requirements and can be flexibly configured and purchased thanks to its modular design.

- Open & networkable

A standardized interface (API) allows ERP systems, cloud applications, and business intelligence tools such as MS Power BI and many other solutions to be seamlessly connected.

- Validated & Qualified

PromasCS is based on a validated, well-documented software architecture with integrated electronic batch documentation (EBR) according to GMP/FDA 21 CFR Part 11 – this significantly reduces the validation effort in customer projects.

The strengths of PromasCS at a glance

Integrated complete solution

One system for PLC, SCADA and MES.

PromasCS combines automation, control level, and MES in a single, integrated platform. This avoids isolated solutions and interface problems, reduces integration and operating costs, and ensures a unified data foundation. One system, one contact person – for maximum transparency, ease of use, and efficient service.

No-Code Process Engineering

Design processes instead of programming them.

With PromasCS, process and production experts can model workflows themselves – without any programming knowledge. Changes can be implemented quickly and reliably, external service costs are reduced, and your production remains flexible and responsive.

Process reliability through automatic mode

Reproducible quality – regardless of the operator.

With PromasCS Batch, recipes are processed automatically, in a standardized and traceable manner. This increases process reliability, reduces error rates, and ensures that every batch is produced with consistent quality. At the same time, it reduces operator workload and utilizes resources efficiently.

Scalable & modular system

Grows with your needs.

Whether laboratory, pilot plant or large-scale production – PromasCS adapts to your needs. You only invest in the modules you actually require, while remaining future-proof for new products, locations or capacity expansions.

Industry focus & compliance by design

FDA and GMP requirements are already covered in the standard.

PromasCS was specifically developed for the pharmaceutical, cosmetics, and chemical industries. Many regulatory requirements are pre-configured and integrated – this reduces customization, shortens project durations, and minimizes validation efforts. Our more than 27 years of industry experience make our product audit-proof, practical, and reliable – giving you the assurance of relying on a proven, regulatory-approved system.

Electronic Record & Documentation (EBR)

Audit-proof, seamless, compliant with regulations.

PromasCS enables the complete electronic recording of all production data in accordance with FDA 21 CFR Part 11. Batches, processes and deviations are documented in a traceable manner at all times – for the highest quality and safety standards.

Minimized validation effort

Be productive faster – with low risk.

Thanks to its high degree of standardization and qualified core software, PromasCS significantly reduces validation effort. This saves time, costs, and resources, ensuring a safe and predictable implementation.

Traceability and transparency

Full control over materials, processes, and batches.

PromasCS offers end-to-end traceability of all raw materials, components, and production steps. This ensures compliance during audits, enables rapid root cause analysis, and reduces risks in the event of deviations.